Contact

Information

UNOZAWA BRAND

- Home

- UNOZAWA brand

UNOZAWA is a dedicated pump and blower manufacturer.

Using our excellent design ability, and production ability based on our rich experience,

we are committed to contribute to solving the problems of our customers and

to achieving the security of facility operations.

Design ability

The most notable strength of UNOZAWA’s products lies in the ability to customize the specifications to those most suitable to the customer’s application. We resolve the customer’s problems by our excellent design ability.

Lifetime

By preserving the production method since the time of our foundation, we are committed to continuing production that assures long life. There are a number of products that have been used in the field by customers for more than 50 years.

Confidence

We have a rich record of delivery to the manufacturing industry and the medical industry, including the major chemical product manufacturers, over a long period of time.

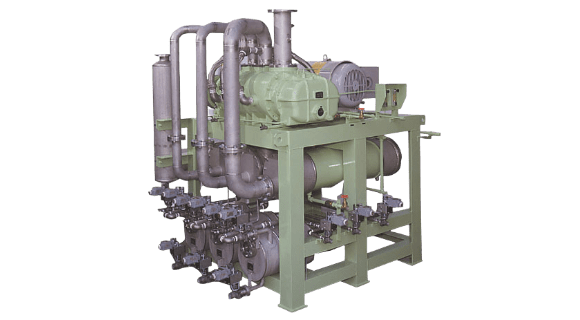

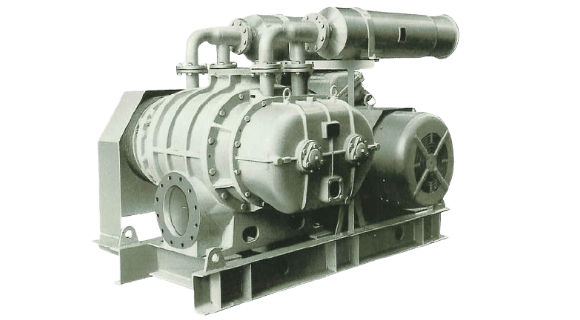

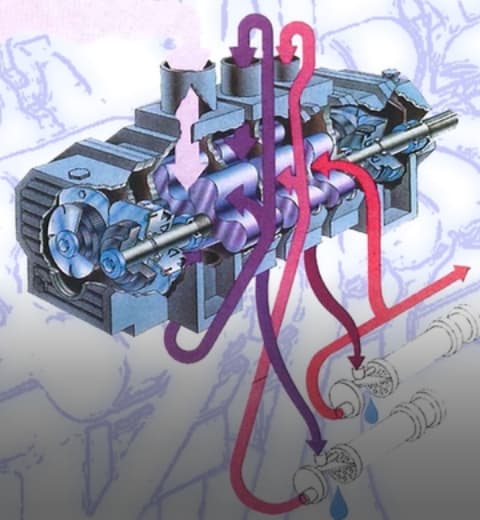

What is a vacuum pump?

A pump is a machine that utilizes the function to suction gas or liquid. A vacuum pump, among others, is to create vacuum by exhausting gas from a container, and there are such types as a dry pump, an oil-sealed rotary pump, and a water ring vacuum pump.

What is a blower?

A blower is a machine responsible for moving either air or gas by such means as rotary motion of rotors. It is widely used in a variety of applications such as transfer of process gas, pneumatic conveying of powders, waste water aeration, combustion air for incinerator.

UNOZAWA ORIGIN

UNOZAWA, after its original operation of producing stained glass, started its business in 1899 aiming to be a domestic pump manufacturer.

Since then, we have operated the business over a century as a dedicated pneumatic and hydraulic machinery vendor.

And in 1981, we succeeded in development of the world’s first dry vacuum pump.

The dry vacuum pump has been widely used as a mainstream product all over the world, and UNOZAWA products have been widely accepted by the manufacturing industry as well as the medical industry, specifically by major chemical product manufacturers.

- In August 1899,

- UNOZAWA was founded at Azabu Shinbori-cho, Minato-ku, Tokyo.

- In December 1907,

- the company moved to its newly built buildings for office and factory at Ebisu, Shibuya-ku, Tokyo.

- In December 1933,

- they changed the organization and established Unozawa-gumi Iron Works, Limited.

- In September 1937,

- the Tamagawa factory was created in Ota-ku, Tokyo.

- In July 1962,

- the Osaka Sales Office was established.

- In November 1962,

- after increasing its capital by 100 million yen, the company was listed on the Second Section of Tokyo Stock Exchange.

- In November 1975,

- the company capital was increased to 510 million yen.

- In February 1977,

- Hydrodynamics Laboratory was newly established in the Tamagawa Factory.

- In September 1977,

- The Shibuya Factory was merged into the Tamagawa Factory for rationalization.

- In March 1984,

- on the former site of the Shibuya Factory, Unosawa Tokyu Building was built jointly with TOKYU LAND CORPORATION.

- In February 1987,

- business collaboration was established with Stokes Vacuum, USA.

- In December 1992,

- the company capital was increased to 785 million yen.

- In August 1995,

- technology was licensed to ACC Machinery Company Ltd. India.

- In December 1996,

- The HQ functions were moved to the Tamagawa Factory.

- In July 1998,

- we obtained ISO9001 certification (UKAS/SGS).

- In November 2003,

- Ebisu Business Tower was completed (jointly owned).

- In June 2005,

- Unosawa Service Center was opened (in Saga Prefecture).

- In February 2007,

- the extension work for the first term company building (factory and office) was completed.

- In November 2007,

- the representative office was opened in Singapore.

- In December 2008,

- the new building for our service factory was completed.

- In January 2011,

- the extension work for the second term company building (factory and office) was completed.

UNOZAWA TECHNOLOGY

While polishing the traditional craftsmanship as a manufacturer,

we are introducing leading edge technologies to support the manufacturing technology of Japan.

In FY 2015, we received “Craftsmanship of Ota-ku for the Next Generation--Excellent technicians for the future of Ota-ku Award.”

In Ota-ku, “Craftsmanship of Ota-ku for the Next Generation--Excellent technicians for the future of Ota-ku Award” was established in FY 2013 to encourage the technicians for the future and to secure and nurture the young people of SMEs in this area.

“Ota-ku Excellent Factory” in FY 2011

We were certified as an “Ota-ku Excellent Factory” in FY 2011.

“Ota-ku Excellent Factory” certification was established in FY 1995

to promote human-friendly (motivating labor environment) industry in Ota-ku.

“Tokyo Governor’s Award for SME Manufacturing Human Resources Education” Encouragement Award

We received the Encouragement Award of The Second “Tokyo Governor’s Award for SME Manufacturing Human Resources Education” in FY 2005. This award has been in place since FY 2004 to award SMEs who have achieved excellent results in building up excellent technicians and retaining technology, thereby improving the education and treatment of technicians and further activating the industry of Tokyo and creating a competitive manufacturing industry in Tokyo.

Approach for nurturing technicians and skill succession

1. An ability-based grade system to meet the contents of each job and execution ability for such contents has been in place.

2. By signing a business outsourcing contract with excellent technicians who are retiring due to age, those seniors are asked to instruct young employees under OJT.

3. The examination fees for technical skill tests and tuition fees for qualification required for jobs are fully paid by the company.

Furthermore, a financial incentive plan for qualified skilled technicians was established in FY 2005.

4. We accept students such as technical high school students as interns, and we are named as the accepting company under the dual system.